If you’ve ever found yourself wondering, “What is plywood,” you might as well have done the research and faced the dozens of choices pushed into you upon hitting “search”. Although choosing plywood can feel overwhelming with so many options, the challenge comes from the right place, because plywood is a versatile and essential building material.

Still, many wonder, “what is plywood used for?” If you’re one of these people, you should know that in this guide, we demystify plywood by explaining how it’s built, the meaning of its grades, and its common uses. You’ll learn about structural, non-structural, marine, and specialty plywood so you can pick the right sheet for your project. With this knowledge, you’ll save time and money and feel confident when tackling any build.

So, if you’re ready to find the answers to your questions, let’s get to it!

What is Plywood? The Basics of its Build

Plywood is an engineered wood sheet made by gluing together thin layers of wood veneer. Each layer (called a “ply”) is oriented so its wood grain runs at a right angle to the layer below. This cross-grain construction is what makes plywood strong and stable; but also costlier than other building options.

The alternating grain pattern in plywood resists cracking, shrinking, and warping as humidity changes. If you’re still not sure, “what is plywood,” think of it this way. Plywood combines the best of solid wood (strength) with dimensional stability to yield panels that stay flat and sturdy under load.

How Plywood is Made: From Log to Sheet

The next common question on our list is, “what is plywood made of”. But let’s take a step back and see how it’s made. The manufacturing process starts with debarked logs that are peeled into thin veneer sheets (often just 0.4–3.2 mm thick) using a rotary lathe or slicing machine.

These sheets are dried and sorted by quality: the best veneers become the front and back faces of the plywood, and the others go to the inner layers. During assembly, each veneer is coated with a strong adhesive and stacked with alternating grain directions.

The veneer stack is then placed in a hydraulic press where heat and pressure cure the glue and bond the layers. After pressing, the panel is trimmed and sanded to size, which results in a flat, rigid plywood sheet. This process ensures the plywood panel is uniform and durable.

Understanding Plywood Grades: The A, B, C, D System

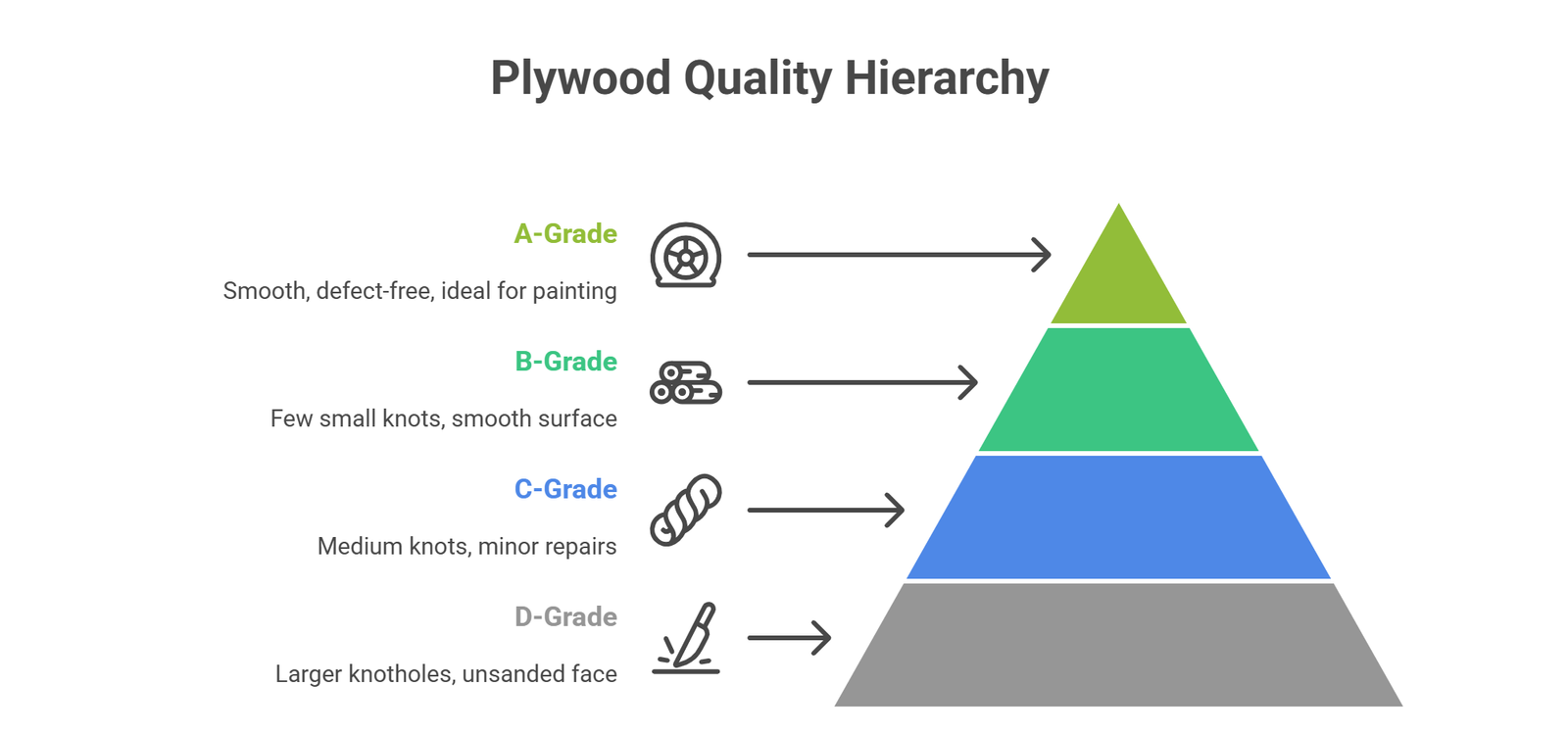

Plywood face and back surfaces are graded by veneer quality using letters A (best) through D (poorest).

- Grade A panels have a smooth, sanded surface with virtually no visible defects, hence becoming an ideal painting option.

- Grade B is nearly as good, in the sense that it may have a few small knots or repairs, but the surface is still sound and smooth enough for visible use.

- C-grade plywood can have medium knots and minor repairs.

- D-grade can show larger knotholes and an unsanded face.

Sheets are often labeled with two grades (like A-C or B-B) indicating the face/back veneer quality. For example, BC-grade plywood has a B-grade front and a C-grade back. Typically, you use the higher-quality face outward (e.g. B side out on a BC panel).

What Is Structural Plywood? The Framework of Your Home

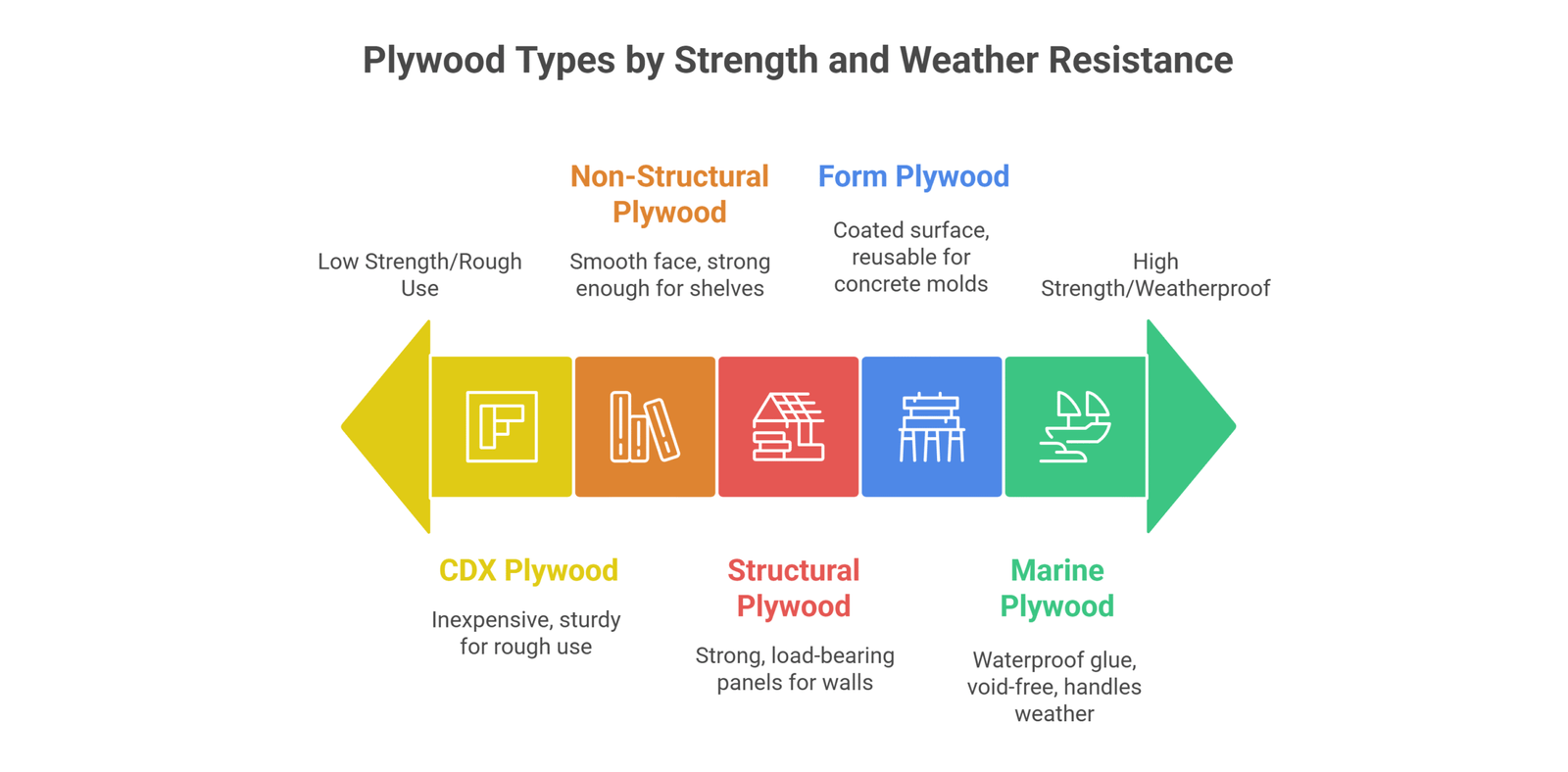

Structural plywood is engineered for load-bearing construction. It’s the stuff used for wall sheathing, roof decking, subfloors and other framing applications where strength matters. Unlike decorative plywood, structural panels are rated by engineered specs (like span rating) rather than appearance.

In practice, structural plywood (often sold simply as “sheathing” or “CDX”) should be covered by siding, underlayment, or finish materials. Its main feature is that it can carry heavy loads safely. If you need to span joists or brace walls, pick a structural-grade plywood.

What Is Non-Structural Plywood? For Interior and Decorative Projects

Non-structural plywood is intended for projects where appearance or interior use is the priority rather than heavy loads. You’ll find it in furniture, cabinet making, shelving, and decorative wall panels.

These panels usually have smoother, finish-ready surfaces (often A-B or A-C grade) so they look good with little or no extra finishing. For example, sanded plywood (with face/back plies sanded) is used for cabinets, shelves, and interior trim.

What you need to keep in mind is that just because non-structural plywood can’t handle the heavy load, it doesn’t mean that it’s inferior. Rather, it’s simply optimised for visual appeal and ease of working. When you don’t need structural strength, but want a nice surface, non-structural plywood is the right choice.

What Is Marine Plywood? The Water-Resistant Specialist

Marine plywood is built to resist moisture and delamination. It uses only high-quality veneers (typically hardwoods) with no voids and a waterproof glue such as phenolic resin. This makes it exceptionally stable and durable in humid or wet environments, such as Australia’s Melbourne and its surrounding suburbs.

Common uses of marine plywood include boat building, dock or pontoon decking, exterior furniture, and wet-area construction (like bathroom vanities or saunas). Keep in mind though, marine plywood is water-resistant, not completely waterproof. This means that while it tolerates prolonged moisture better than regular plywood, it still needs sealing for a long life.

In short, you can use marine plywood wherever serious moisture or splashes are expected (for example, boat or seaside projects).

What Is Form Plywood? The Concrete Mold

Form plywood (also called concrete form plywood) is a specialty panel designed purely for concrete work. Its face is coated or laminated to create a very smooth, non-stick surface. This smooth coating prevents freshly poured concrete from bonding to the plywood, and allows easy removal once the concrete cures.

Form plywood is also built extra strong and moisture-resistant so it won’t warp under the weight and wetness of poured concrete. In practice, you’ll see it used in making temporary molds for foundations, walls, columns and slabs. High-quality form plywood can be reused many times, hence gaining the title of the concrete forming’s workhorse.

Putting It All Together: A Project Guide

Below, you’ll see a number of restoration and home decor projects that require plywood. The goal is to get a feel of what type of plywood is right for each one, so pay close attention:

- Building a Shed: Use structural plywood (rated for framing) for the walls, roof and floor. It will give you strong, load-bearing panels.

- Building a Bookshelf: Choose non-structural plywood in a good face grade (for example, BC or AC). This will look good (a smooth B or A side) and is strong enough for shelves.

- Building an Outdoor Planter or Bench: Go with marine plywood. Its waterproof glue and void-free layers will handle weather and humidity. It also keeps its shape even when wet.

- Pouring Concrete Steps or Forms: Use form plywood with its coated surface for the molds. It won’t bond to the concrete and can be reused.

- Temporary Work Table or Garage Floor: A sheet of CDX plywood (with C/D faces and exterior-rated glue) works well here. It’s sturdy and handles occasional moisture, and is inexpensive for rough use

How to Choose the Right Plywood for Your Project

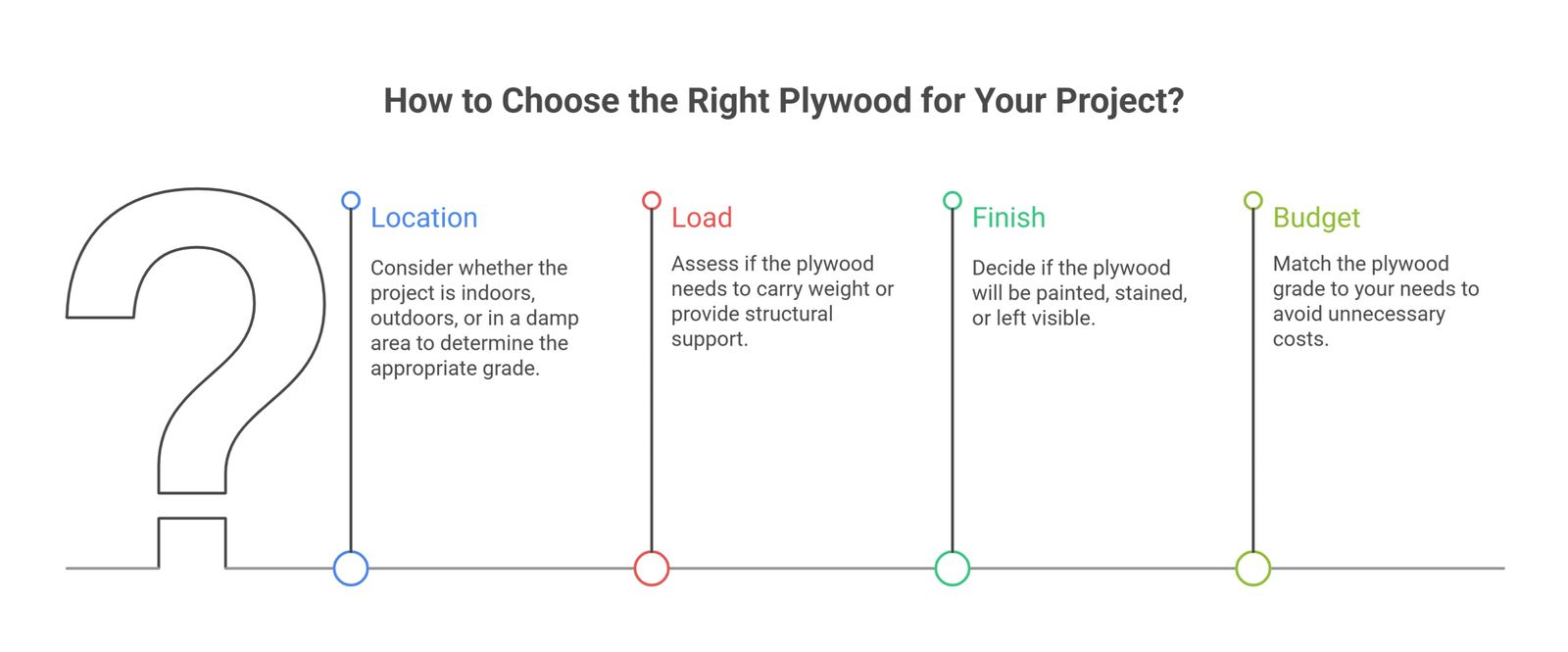

Before you shop, run through a quick checklist:

- Location: Will your project be indoors, outdoors, or in a damp area? (Outdoor or wet environments call for exterior-grade or marine plywood.)

- Load: Does the panel need to carry weight or provide structural support? (If yes, use structural-rated plywood; if not, decorative grades are fine.)

- Finish: Will the plywood be painted, stained, or left visible? (Higher grades like A or B have smooth faces for painting; lower grades can be hidden.)

- Budget: Higher-grade and specialty plywood costs more. Match the grade to your needs so you don’t pay for unneeded quality.

Making a deliberate choice at these steps will ensure you get the right plywood sheet for the job.

Quality Plywood at an Affordable Price

As mentioned earlier, plywood can be an expensive material, especially when you’re after premium grades like marine or form plywood. The cost often reflects its durability and versatility, but it can still feel like a big investment for homeowners or builders.

That’s where Silk Touch Joinery steps in. Our team sources high-quality plywood and materials at competitive rates, to help clients achieve beautiful, long-lasting results without exceeding their budget.

We specialise in custom cabinetry and joinery services across Melbourne and its surrounding suburbs, including Camberwell, Hawthorn, Kew, Richmond, Toorak, Malvern, Glen Iris, Brighton, and Balwyn. So, if you’re planning a kitchen renovation, looking for storage ideas, or even designing a custom wall unit, our expert craftsmen can guide you on the best plywood type and finish for your space.

Conclusion

In this article, we answered the question, “what is plywood?” In short, plywood is more like a family of products rather than one material. Choosing the right plywood means matching the type of panel (structural, interior, marine, form, etc.) to the demands of your project.

By understanding the differences (from load-bearing sheathing to smooth cabinet-grade sheets to moisture-proof marine panels) you can avoid costly mistakes and ensure your project turns out great. Armed with this knowledge, you’ll save time and money and complete your next project confidently. And if you ever need expert advice or custom solutions, Silk Touch Joinery is ready to help. Don’t hesitate to book a free consultation to find the perfect plywood for your needs.